On this episode of Ask The Expert, Otto explains why our speaker cones have small, rectangular slots around the central dome. Far from being a random happenstance, these small holes actually serve a purpose… oh, and they're not actually holes! ⁉️

Don't forget that without your contributions, Ask The Expert just wouldn't exist as a concept. We appreciate each and every questions, so please keep sending them in. You can do so by submitting them on the form "Send us your questions" at the bottom of this page.

Why are there holes in Dynaudio’s speaker drivers?

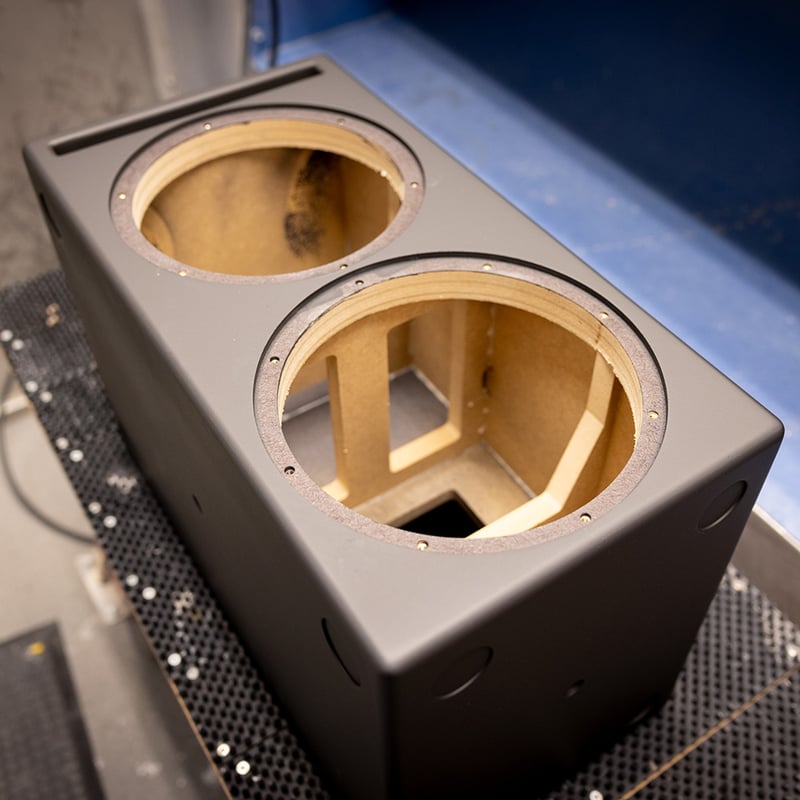

This is an interesting question which refers to the square-ish holes around the center dome of the speaker driver itself. So why are they there? And what do they do? What's the purpose of these holes? To answer that question, it makes most sense to talk through how we actually manufacture these speaker cones.

Our speaker cones are made of a material called MSP, which is what all Dynaudio’s woofers are made from. MSP stands for Magnesium Silicate Polymer, and is a blend of different things, resulting in a material with some very specific properties that are great for speaker cones.. MSP – in our eyes – offers the optimum combination of damping, stiffness and lightness.

To make the speaker diaphragms, we have a mould, shaped like the part of the cone that we would like to create. We take a piece of MSP, heat it up and then vacuum-form it over the mould. Once the material has been vacuum-formed onto the mould you get a sheet og MSP with the actual shape of each speaker cone.

On the back of the cone there are dents. So it's not actually holes you can see from the front of the cone, but rather the inside of these dents, which are on the back of the cone. The final step is to cut the cone out and glue on the surround.

Back to the initial question then: why do we have those dents in the first place? There are actually three different reasons for this:

– The first reason is to do with the voice coil alignment. By using the dents, the voice coil is automatically perfectly centered onto the diaphragm, which would not be the case if it was just a completely round dome – it would simply be more difficult to centre it. Thanks to the dents, there is only one perfect "dead center" position.

– The second reason is that these dents actually create a coupling point between the voice coil and the middle part of the dome, causing the coupling to become stiffer. That helps the high frequency response of the woofer because the high frequencies emanate mostly from the center dome and not from the rest of the cone itself. So having a proper coupling between the coil and the center dome improves the high frequency response of the driver.

– The third reason is that – when we glue the voice coil to the diaphragm – we get a bigger gluing surface with the dents, and so we have a much larger surface between the cone itself and the voice coil former. So that gives a better power handling.

Once we have glued the voice coil onto the diaphragm and mounted the spyder we have a complete moving system which needs to be centered perfectly in the woofer basket. In order to do this – incidentally – we actually do need some holes in the diaphragm.

When we centre the system inside the basket, we make three small pinholes and then put three small pieces of piano wire through these holes. Once the glue is dry, we pull out the piano wire and then we close these three holes with a tiny piece of glue, ensuring that everything is sealed and completely airtight again.

All these small details add up to what becomes a Dynaudio driver, where every detail is optimised for achieving the best sound quality possible. This makes a Dynaudio driver fairly complicated to manufacture because there's a lot of individual processes, but the end result is a better-sounding loudspeaker for the end consumer.

Send us your questions

Don't forget to submit your questions to our experts via the form below – they might just get featured in a future episode of Ask The Expert!